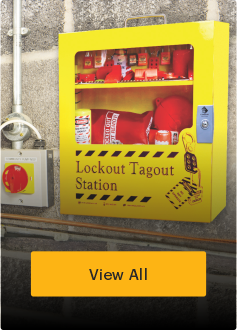

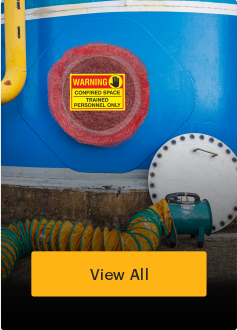

8 Steps to Apply Lockout Tagout

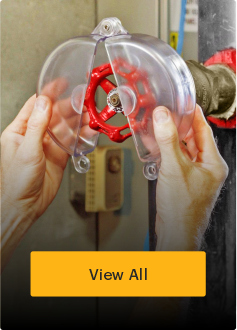

Spread the loveThe bustling environments of industries often hide potential dangers, especially during machine maintenance and servicing. Unexpected equipment startups or sudden energy releases can have catastrophic results. Thankfully, with careful adherence to OSHA’s Lockout Tagout standard, such risks can be significantly mitigated. This guide presents an 8-step comprehensive approach to ensure a safe and […]