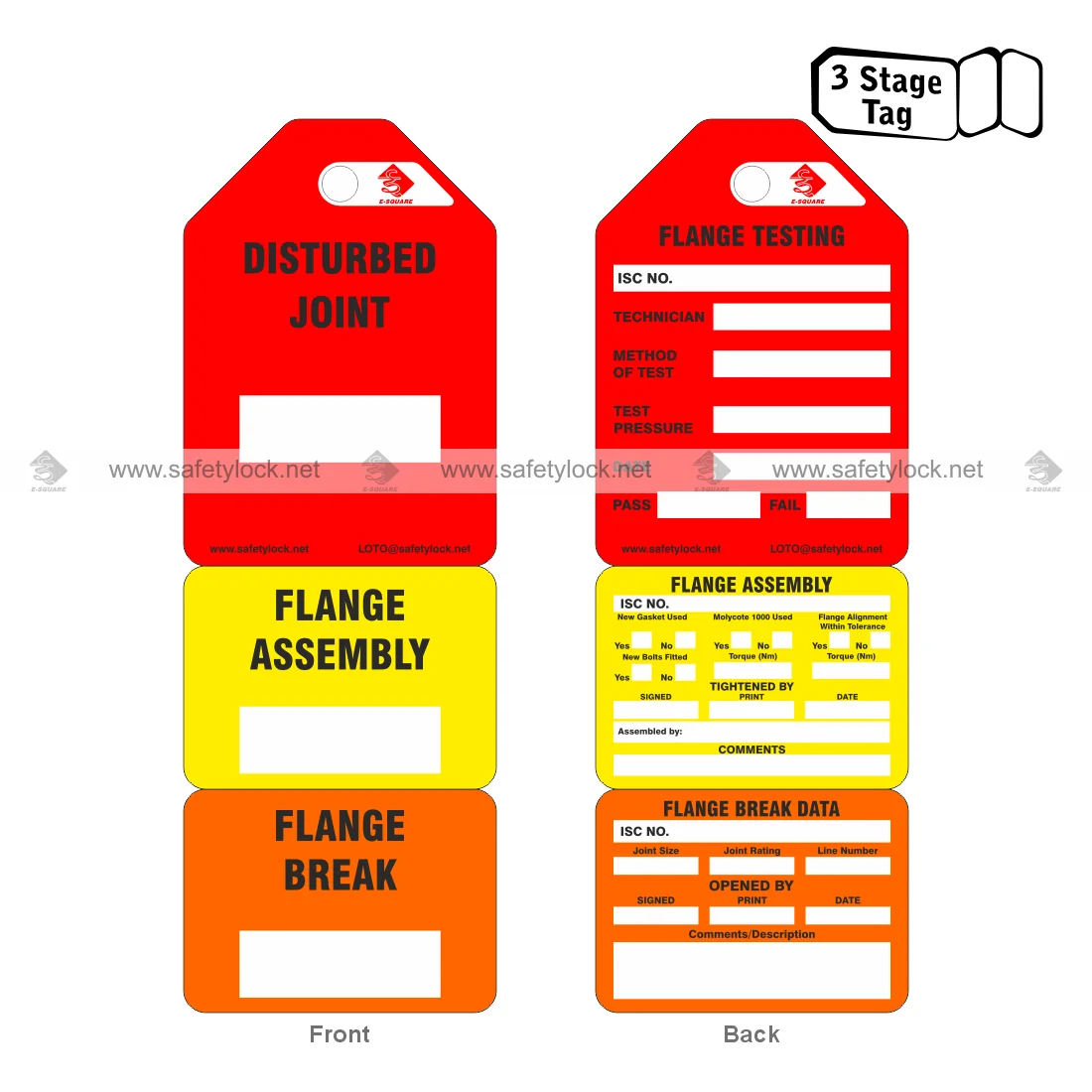

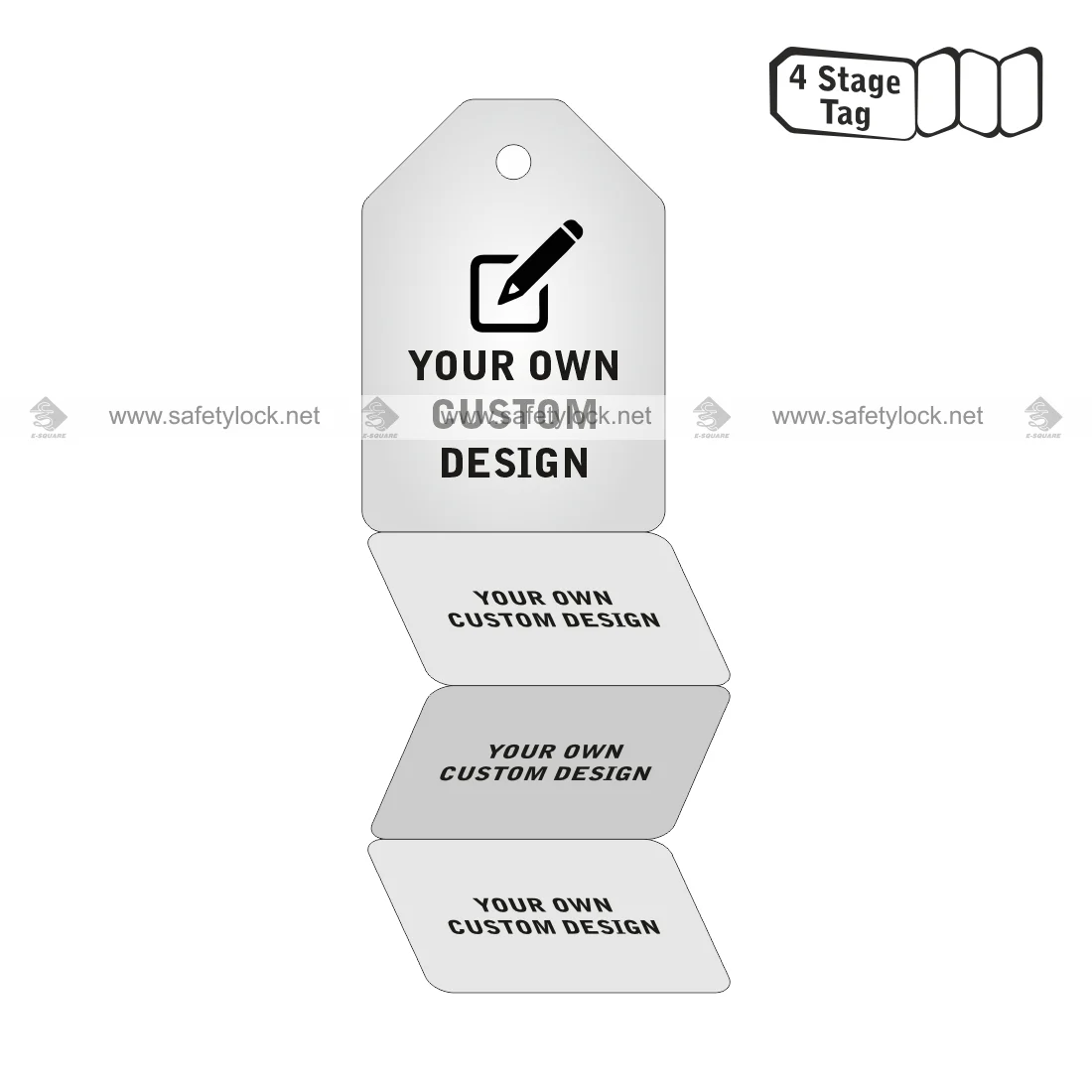

Product Description

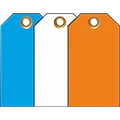

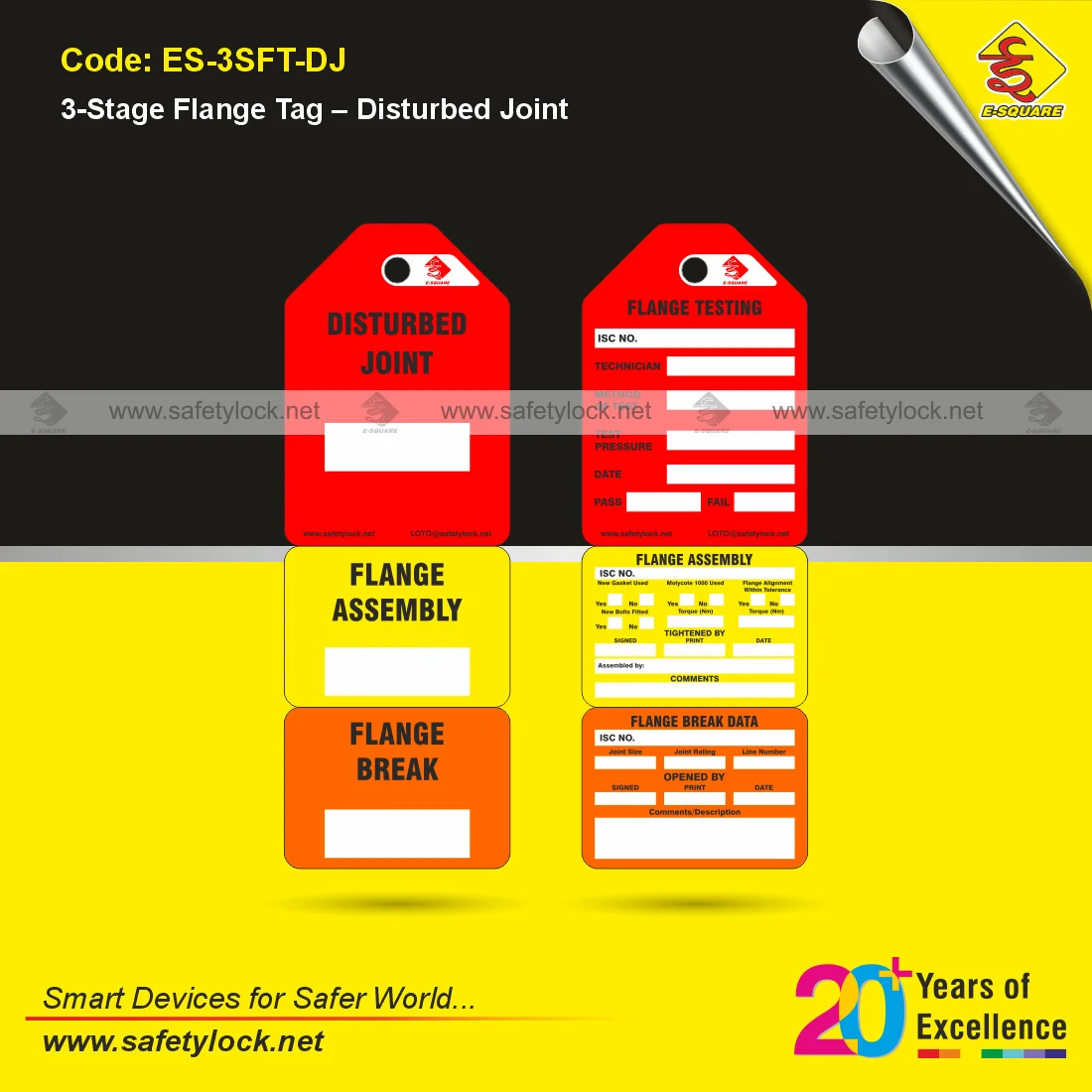

- Provides a 3-stage visual checklist specifically for disturbed joint flange management:

- Disturbed Joint (Red): Immediate indication that the joint has been disturbed and is unsafe to operate.

- Flange Assembly (Yellow): Documents assembly details such as gasket use, torque values, flange alignment, inspector and assembler signatures.

- Flange Break (Orange): Records disassembly details, joint size, rating, and line number, ensuring traceability.

- Acts as a lockout-tagout extension, preventing accidental system energisation when a flange joint is disturbed.

- Human Error Reduction: The tag enforces a methodical, auditable workflow by requiring each stage to be signed and recorded.

- 3-stage flange tags – Disturbed Joint is manufactured using durable 0.5mm PVC sheets.

- Also Available in durable PVC (0.3mm, 0.7mm) or Non-Tearable Paper, ensuring long-lasting use (MOQ Applicable).

- Tear-resistant and weatherproof; resists oil, water, dirt, and chemicals, suitable for harsh industrial environments including offshore rigs, refineries, petrochemical plants, and power stations.

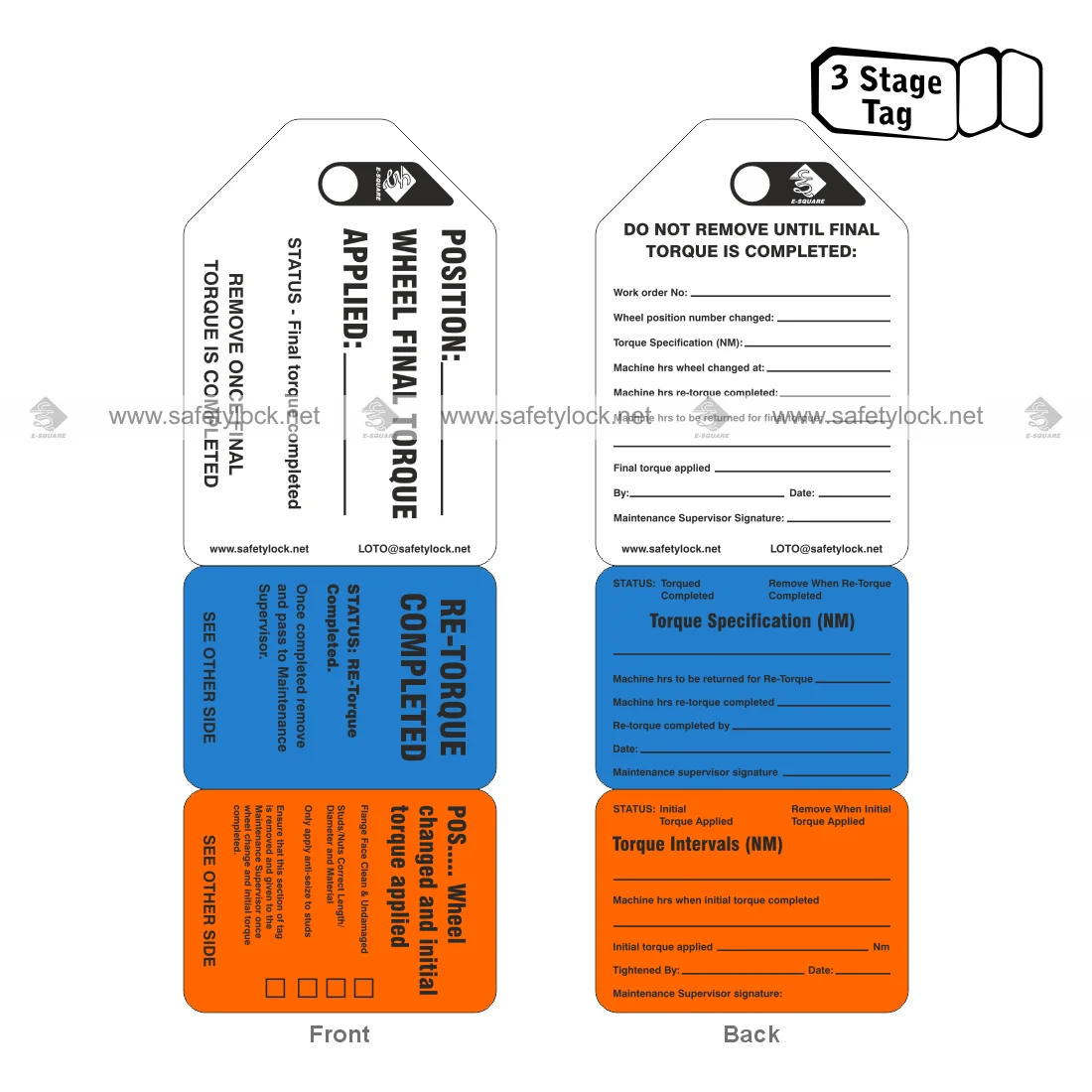

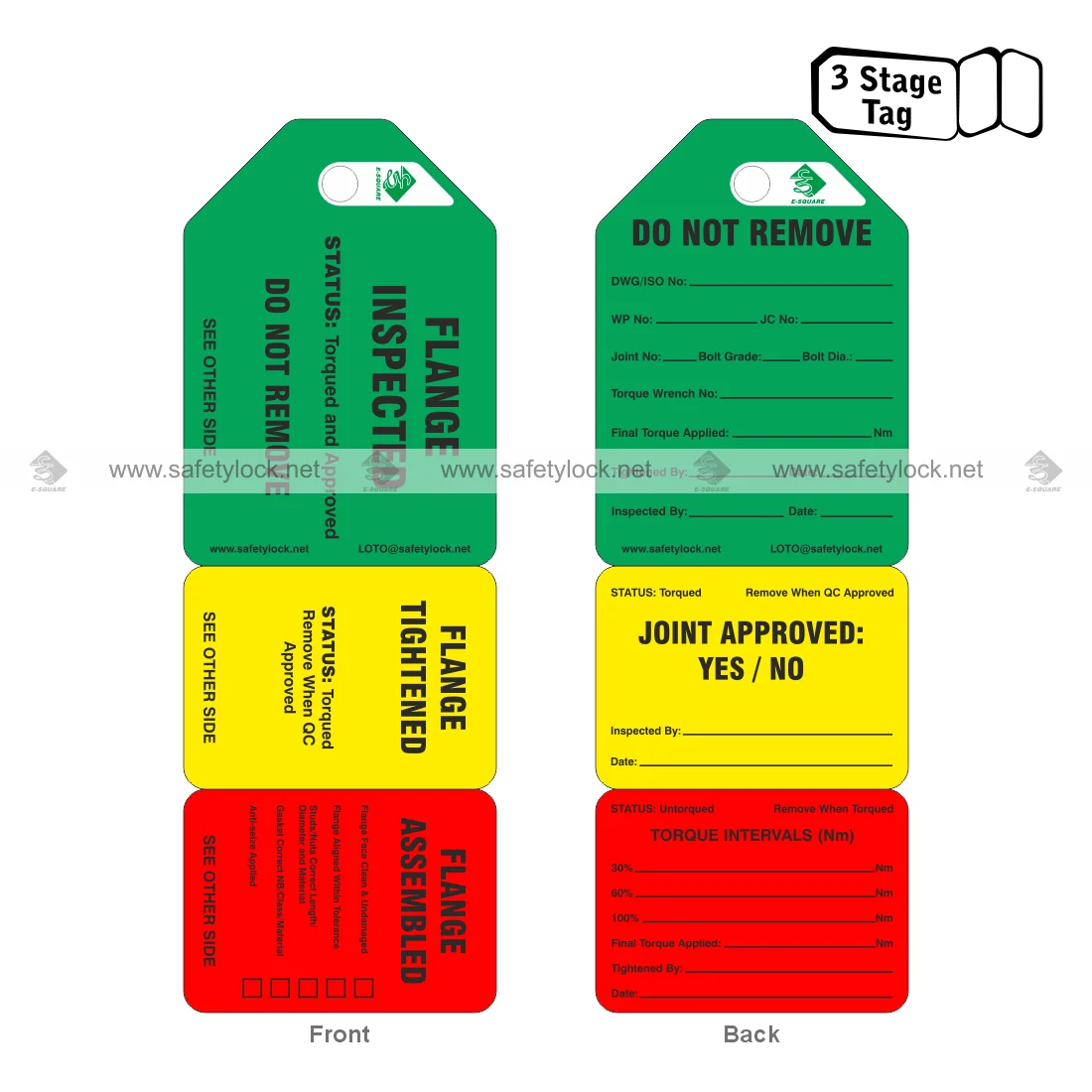

- Writable surfaces for recording torque values, inspector signatures, dates, and other critical data.

- Audit-ready system: Retained tag sections serve as a permanent signed record for compliance, troubleshooting, and historical tracking.

- Includes fields for ISC No., Technician details, Assembly/Break data, and Test Results, ensuring complete documentation.

- 8mm pre-punched mounting hole at the head allows secure attachment using cable ties.

- Suitable for commissioning, shutdowns, turnarounds, and maintenance where disturbed joints present elevated safety risks.

- Aligns with industry best practices for flange management, ensuring standardisation across multiple teams and contractors.