- Lockout Tagout

- Lockout PADLOCKS

- PLUG Lockout

- Key CABINETS

- BLIND FLANGE Lockout

- Lockout Tagout KITS

- PIN and SLEEVE Lockout

- MSDS CABINETS

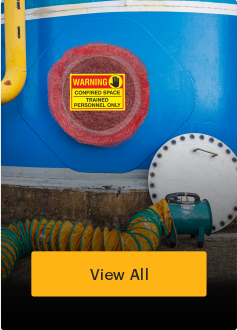

- CONFINED SPACE Cover

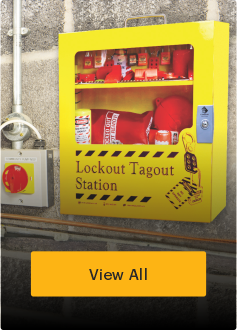

- LOTO STATIONS

- CABLE Lockout

- Lockout BAG and POUCH

- ENERGY SOURCE ID Tags

- VALVE Lockout

- Lockout HASP

- LADDER Lockout

- Lockout SIGNS & LABELS

- CIRCUIT BREAKER Lockout

- CYLINDER Lockout

- BLOCKING BAR Lockout

- Lockout SAFETY BANNER

- Lockout SAFETY TAGS

- SHADOW LOTO Station

- FUSE Lockout

- Lockout Safety POSTERS

- ELECTRICAL PANEL Lockout

- OPEN Lockout Station

- PNEUMATIC Lockout

- STEERING WHEEL Covers

- GROUP Lockout Box

- Padlock CABINETS

- LOTO ACCESSORIES

- SINGLE USE LOTO

- Lockout Padlocks

- Lockout Tags

- Electrical Lockout

- Mechanical Lockout

- Lockout Tagout Kits

- Stations and Cabinets

- Related Products

- Customised LOTO